Molded Rubber Engine Gaskets

From valve cover gaskets to oil pan gaskets, many of today’s engines use molded rubber gaskets. While molded rubber gaskets were introduced in the 1960s, they became widely used in the 1980s and 1990s for valve covers, oil pan gaskets, timing cover gaskets, and intake manifold gaskets.

What Type of Rubber is Used for Gaskets?

While molded rubber is common on modern vehicles, the types of rubber formulations can vary between manufacturers. Although the rubber compound of some gaskets may appear similar – even attempting to mimic the look of Fel-Pro® products – the similarities end when the gaskets are put to the test in the repair environment. Visually comparing two gaskets won’t show the differences between the molded rubber properties and formulations.

Fel-Pro’s proprietary in-house molded rubber technologies are unrivaled in the industry. All materials are tested and validated to ensure every gasket is manufactured using the best material for that specific application. Two of the most common molded rubber types used in Fel-Pro gaskets are silicone rubber and fluoroelastomer (FKM).

Silicone Rubber

There are many different types of silicone rubber. At Fel-Pro, we maintain control over the exact blend of compounds used to create the rubber, testing each batch. This quality control continues through the manufacturing process, ensuring the mix is perfect. In-house manufacturing also allows us to make different blends of rubber for different applications, to suit specific needs.

The advantages of Fel-Pro’s silicone rubber are its long life, high temperature and oil resistance, and its ability to be used as a flexible press-in-place gasket or molded over a rigid carrier for easy installation and high vacuum holding capabilities. Silicone’s ability to resist extreme temperatures and maintain sealing pressure over time makes it ideal for sealing a wide variety of oil applications, such as valve cover, timing cover gaskets, and oil pan gaskets.

Fluoroelastomer/FKM

Fluoroelastomer, also known as FKM, is a synthetic rubber compound that has resistance to a wide variety of chemical compounds. At Fel-Pro, we use our proprietary FKM formulation, designed specifically to hold up to the chemicals found in modern engine fluids.

FKM can be used for molded rubber gaskets and as a gasket coating. Fel-Pro engineers use a blend of ingredients to make a proprietary FKM rubber that is impervious to all types of oils and fluids. This premium rubber is molded to a rigid carrier system, like the Fel-Pro PermaDryPlus® intake manifold gasket product line. Its proprietary properties make it ideal for intake manifold gasket sealing, where exposure to the corrosive properties of some coolants can cause premature gasket failure. FKM is also ideal for use as a MLS head gasket coating, since it is conformable enough to seal minor surface imperfections, while being dense enough to retain torque and, at the same time, resist high engine operating temperatures.

The Fel-Pro Gaskets Advantage

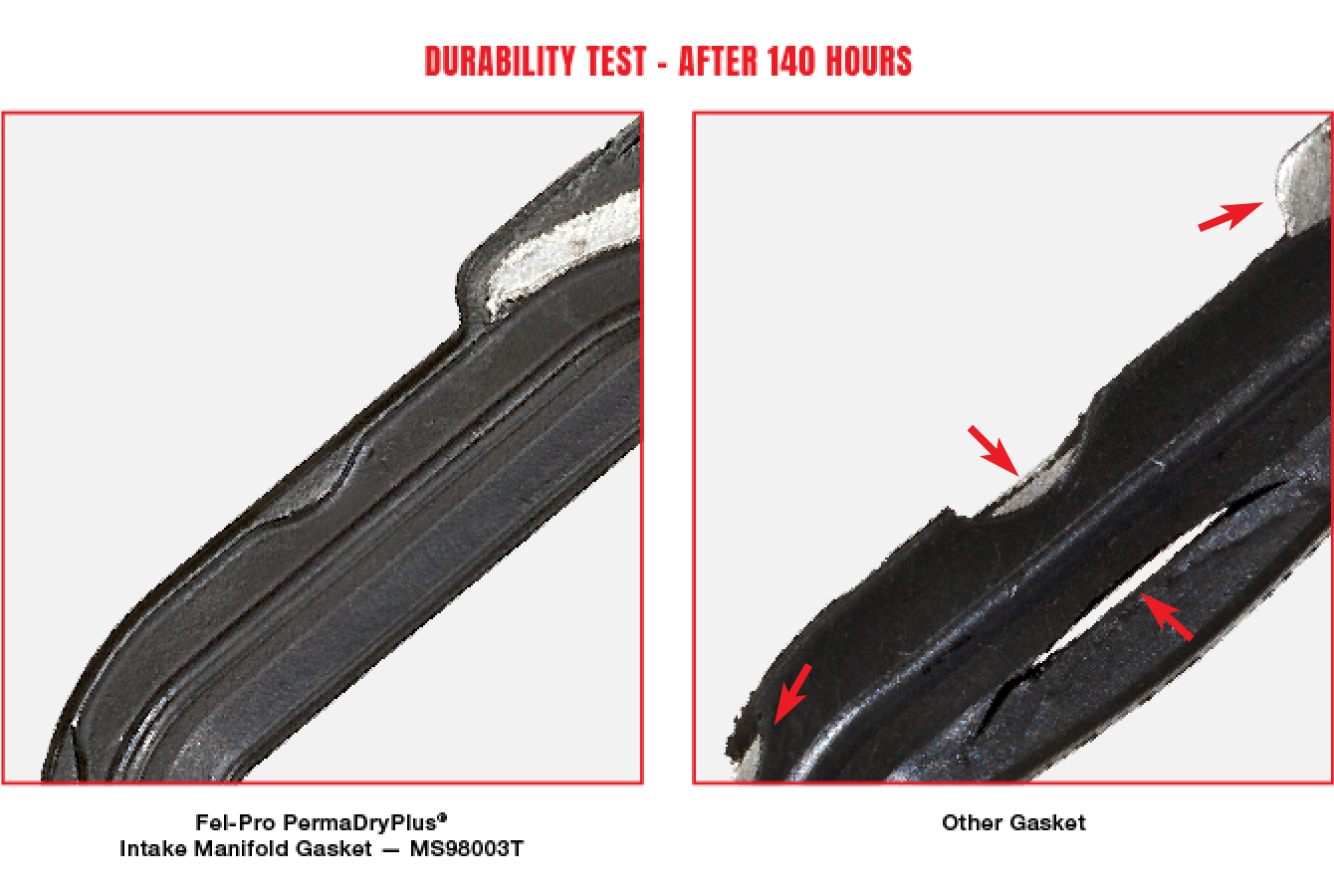

The durability of the Fel-Pro PermaDryPlus intake manifold gasket MS98003T was tested against that of another gasket; the results were telling. With the Fel-Pro gasket installed on one side of an engine, and the other gasket installed on the opposite side, the engine was run on a dynamometer. After 140 hours, coolant began leaking around the non-Fel-Pro gasket.

The Fel-Pro gasket retained more than 85% of its compression recovery and experienced zero leaks, splitting, or cracking. When testing resumed with the same Fel-Pro gasket, it continued to perform for the duration of the test cycle.

In stark contrast, the rubber on the other gasket had split; its rubber compound was inferior and unable to withstand the corrosive effects of the coolant. The other gasket’s rubber sealing beads also lost their ability to recover from compression, indicating a shortened sealing life. In addition, the metal compression limiter had cracked, which can affect torque retention.

You can count on Fel-Pro for the ideal replacement gasket with product designs that address the unique demands and operating environments of every application.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.