What is Cylinder Head Lift?

Cylinder head lift is a phenomenon that occurs when the cylinder pressure in an internal combustion engine causes the head to lift away from the deck surface of the engine. In minor cases, this can result in combustion gasses entering coolant passages. This pressurizes the cooling system and pushes coolant out of the cooling system, which will lead to overheating. In more severe cases, head gasket damage can occur, leading to head gasket failure.

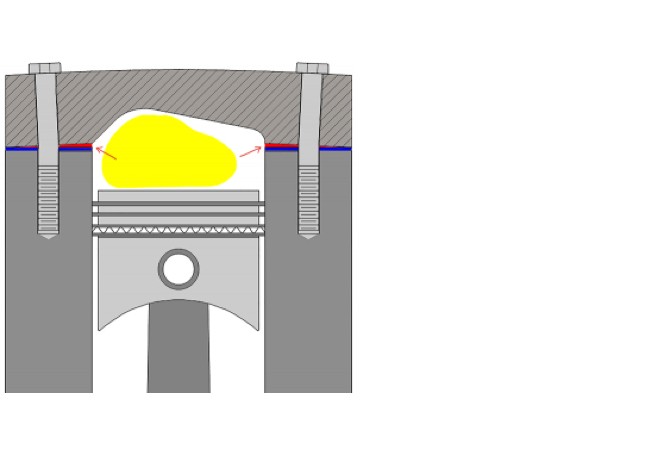

The illustration here depicts a cylinder head that is lifting during the combustion cycle. The red area above the head gasket is the gap created by the lifting. This gap fills with hot combustion gasses and the corrosive air-fuel mixture.

Preventing Cylinder Head Lift

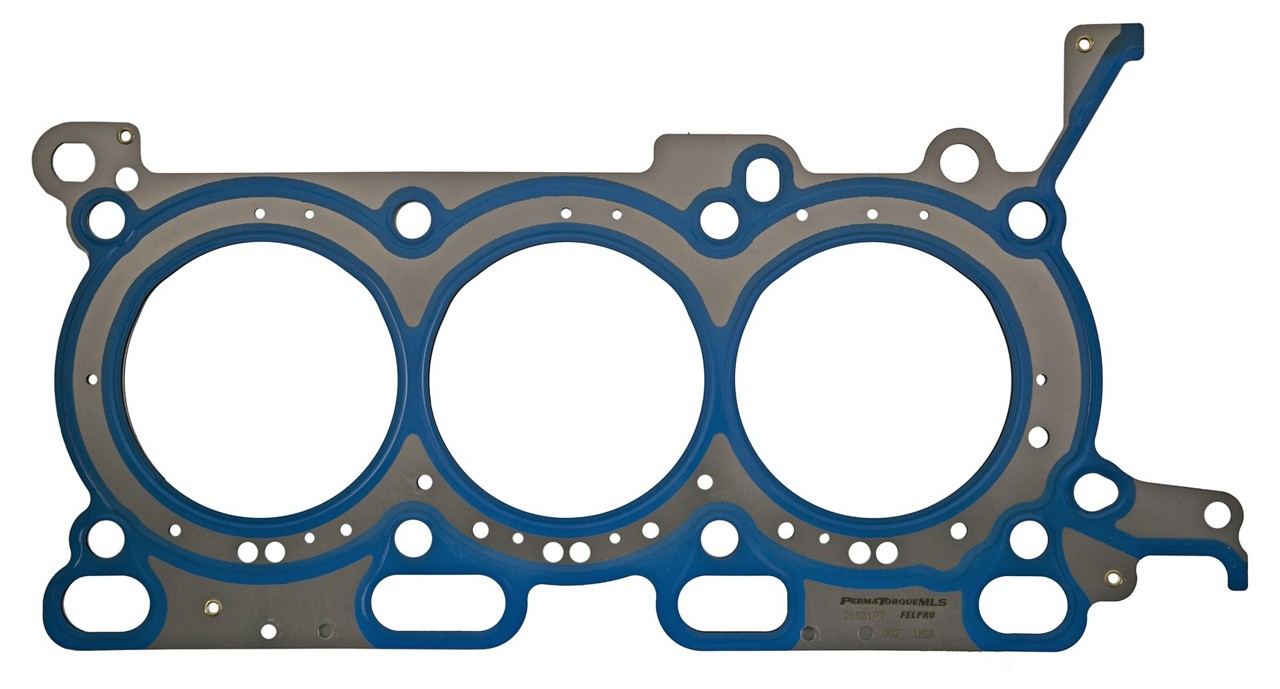

Fel-Pro PermaTorque® MLS head gaskets are the ideal way to combat head lift. Application-specific and designed for the repair environment, Fel-Pro PermaTorque MLS head gaskets are extensively tested. Using extremely sensitive instruments, Fel-Pro’s test engineers take precise measurements of head movement and then design the gaskets to compensate. Key features include:

- Multi-layered steel construction

Multiple layers of stainless steel to maintain shape and accommodate head lift - Proprietary coating

Exclusive coating helps to compensate for rougher sealing surface finishes up to 80 Ra - Superior seal

Precise embossed sealing beads at vital areas to eliminate leak paths - LaserWeld™ stopper layer

Exclusive application-specific technology reduces gasket damage from blow out and helps ensure a stronger combustion seal - Unique combustion seal

Accommodates the high cylinder pressures and head movement associated with engines - Handles extreme engine conditions

Engineered and manufactured to inhibit over-compression of embossments to maintain seal under peak combustion pressures and temperatures

Other things you can do to reduce the possibility and severity of head lift:

- Use the appropriate block and heads for the application, and make sure the surface finish matches the specifications called for (based on gasket material).

- Use the appropriate head fasteners. Always replace Torque-To-Yield head bolts with new T-T-Y bolts. If the engine is going to be used in a performance application, consider the use of high strength head studs or bolts. Always follow the proper torquing instructions for head fasteners to ensure optimal clamping load.

- Avoid cylinder pressure spikes. You can do this by always using fuel that meets the minimum required octane recommendation, especially in high-compression or forced induction engines. Also, make sure that replacement spark plugs are the correct material and heat range for the application. If modifying an engine to make more power, take appropriate action to support these modifications.

Causes of Cylinder Head Lift

Cylinder head lift is caused by excessive cylinder pressure, which can result from several things, including detonation and/or pre-ignition; improper fuel type; over-advanced ignition timing; improper air-fuel ratio; vacuum leaks; malfunctioning sensors; and increased boost pressure.

Detonation, also known as knock, is one of the most common. During normal combustion, the spark from the spark plug ignites the air-fuel mixture, which leads to a controlled burn and normal cylinder pressures. When knock occurs, another flame front occurs outside of the spark-induced flame front, causing uneven burn and creating shock waves. Cylinder pressures spike when this happens, exceeding the pressures the cylinders and head gasket were designed to hold.

Over-advanced ignition timing can also cause knock. Modern engines have electronically controlled timing systems that can reduce timing advance if knock is detected. If the wrong grade of fuel is used and the vehicle’s computer does not adequately adjust the ignition timing, knock can still occur, and cylinder pressure will still spike.

High compression ratios and forced induction (by the means of supercharging or turbocharging) are ways to increase either performance or fuel economy. Unfortunately, head lift is a common problem for these applications too. When air is compressed, it heats up. Hotter air entering the cylinder increases the likelihood of detonation. Cylinder pressures are also greatly increased when boost pressure is increased to make more power, even if detonation is not occurring.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.