Small But Mighty

Different than other seals in the engine, valve stem seals play an important role in lubrication. Valve stem seals allow a controlled amount of oil to lubricate the valve stem as it moves in the valve guide. The amount of oil that passes by the valve stem seal must be precisely controlled. Too little oil causes stem and guide wear; too much oil causes carbon buildup leading to valve seat damage, decrease in volumetric efficiency, increased emissions, catalytic converter degradation and excessive oil consumption.

Stem Seal Designs

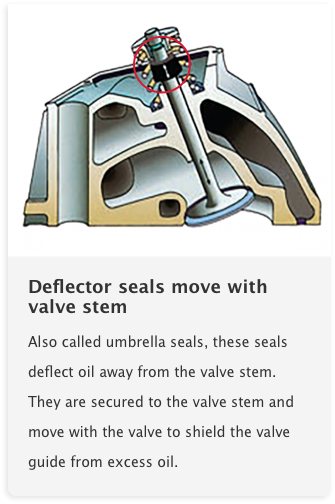

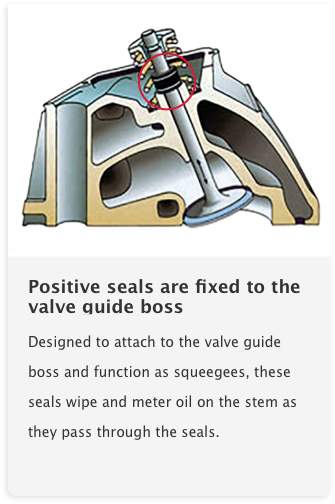

There are two basic stem seal designs - deflector and positive seals.

Fel-Pro® Valve Stem Seals

Fel-Pro engineers analyze the OE design for every application. The OE design is tested and benchmarked. Based on the analysis, we determine the material used, considering the durometer (relative hardness) of the rubber, temperature requirements (both extreme heat and extreme cold), resistance to common oil types, tear-resistance and leak rate.

This type of analysis makes one thing clear, not all valve stem seals are created equal. Visually, a lower-quality seal may look very similar to a high-quality seal that’s appropriate for a given engine platform. However, a lower-quality seal with insufficient heat-resistance will harden and crack prematurely and will not work as intended.

You can count on Fel-Pro to use the right material for each application. Fel-Pro uses a variety of materials including nylon, PTFE, rubber, steel and synthetic rubber or some combination of these. FKM, fluoroelastomer, is used in many Fel-Pro valve stem seals for hotter-running, late-model vehicles. It is often combined with a metal jacket or covering that totally surrounds the FKM positive seal. FKM offers excellent resistance to both heat (up to 450°F) and abrasion.

Installation Tool

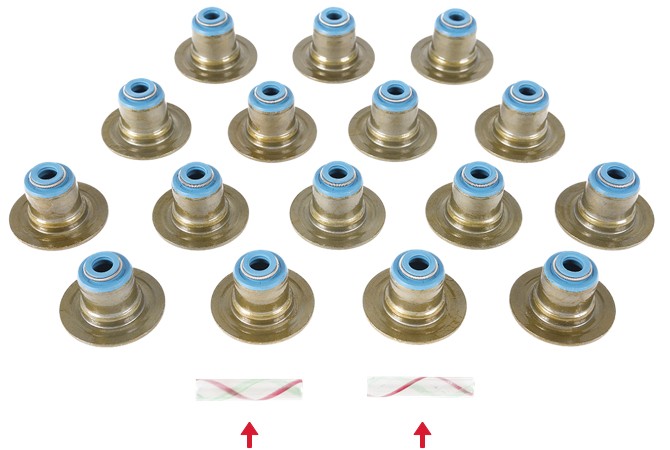

On some applications, the valve stem seals are interchangeable between the intake and exhaust valves and will look exactly the same. On applications which use different seals on the intake and exhaust valves, due to needing higher temperature material on the exhaust side or different design, the seals will be bagged and labeled appropriately.

An installation tool is included in Fel-Pro valve stem seal (VS) sets. This tool is a thin plastic sleeve which is placed over the tip of each valve stem during installation. It protects the inner lip of the seal from damage by the lock grooves in the valve stem.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.