LASERWELD™ STOPPER LAYER: WHAT IS IT?

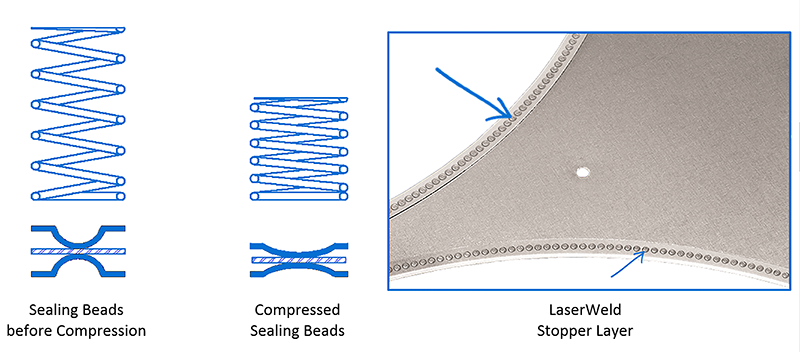

Let’s say you have an engine that needs head gaskets. You know you’re going to use a set that contains Fel-Pro® PermaTorque® MLS head gaskets because you want to use the best technology to ensure a reliable seal. So you get a Fel-Pro PermaTorque MLS head set, open it up and check out the head gasket(s). You notice a ring with small, evenly spaced “dots” all around it between the layers around each cylinder opening. This stainless steel ring and the many tiny spot welds made by a precision laser are the Fel-Pro PermaTorque MLS LaserWeld™ stopper layer.

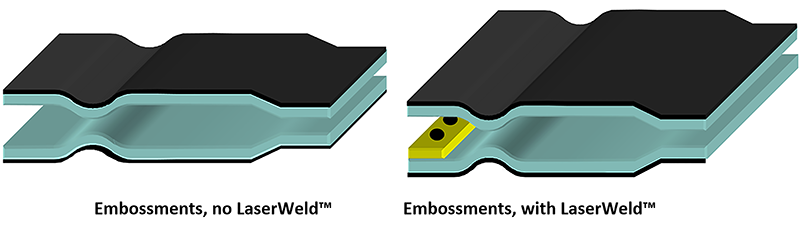

The LaserWeld stopper layer takes the proven PermaTorque MLS design to the next level. On a traditional MLS head gasket, the embossed beads create the combustion seal. The PermaTorque MLS head gasket with LaserWeld has two combustion seals – the LaserWeld stopper layer acts as the primary combustion seal, while the embossed beads act as a secondary combustion seal.

LaserWeld serves two important functions: aside from creating a more robust combustion seal than traditional MLS head gaskets, it also acts as a stopper layer. All Fel-Pro MLS head gaskets are made of multiple layers of stainless steel stamped with embossments that create sealing beads. These embossments act as springs and function best when they are allowed to stay within a certain range of compression between the cylinder head and block. When over-compressed, they cannot fully spring back or “recover,” and leaks can result.

Compression of the multiple stainless steel layers that make up the gasket is precisely controlled by the LaserWeld stopper layer. The LaserWeld stopper layer provides a positive stop, preventing over-compression. This ensures the sealing embossments maintain maximum recoverability and function as designed. LaserWeld is a patented process. US Patent # 7,374,176 B1

The LaserWeld stopper layer also helps reduce head lift by allowing for proper sealing stress between the cylinder head and the block. This vital function also helps to more uniformly load the cylinder bore emboss bead, while ensuring a superior combustion seal. In addition, fatigue life and gasket recovery (in situations where head lift is a factor) are greatly improved.

It should be understood that LaserWeld is not a “one-size-fits-all” approach. Every application that receives a LaserWeld stopper layer goes through specific testing to determine how much additional sealing stress is needed to create an optimal seal. This means dies are designed, manufactured and maintained in-house for each gasket, so there is total control over the manufacturing process.

Fel-Pro Performance Product Manager Ron Rotunno puts the need for precision control into perspective: “There are a number of steps in the development process of a PermaTorque MLS head gasket. This process usually begins with a conversation with an engine builder, race team, a casting manufacturer or a customer. Once the need is identified, we’ll do in-house development work to make sure we understand and benchmark the dynamics of a given engine platform. Engineering starts the design process using computer-generated analytical tools, head lift data, and FEA (Finite Element Analysis) results. Prototype gaskets are made and tested and evaluated before release to production. An extremely high level of control is maintained over each aspect of the process, from raw materials to our in-house manufactured tooling. I can’t overstate the importance of each layer being made to exact specs. The bead height, width and overall profile have to be exact every time.”

Fel-Pro PermaTorque MLS head gaskets use LaserWeld when additional sealing stress is needed. If a PermaTorque MLS Head gasket does not feature LaserWeld, it simply means the emboss beads provide a reliable seal for that specific application.