Gaskets for the Repair Environment

Engineering and manufacturing gaskets for the auto technician is at the heart of what we do at Fel-Pro®. And nothing embodies this spirit better than the phrase “Designed for the repair environment.” Have you ever thought about what this expression means for the auto technicians who use Fel-Pro gaskets? There is more to this simple phrase than meets the eye.

Sealing Imperfect Surfaces

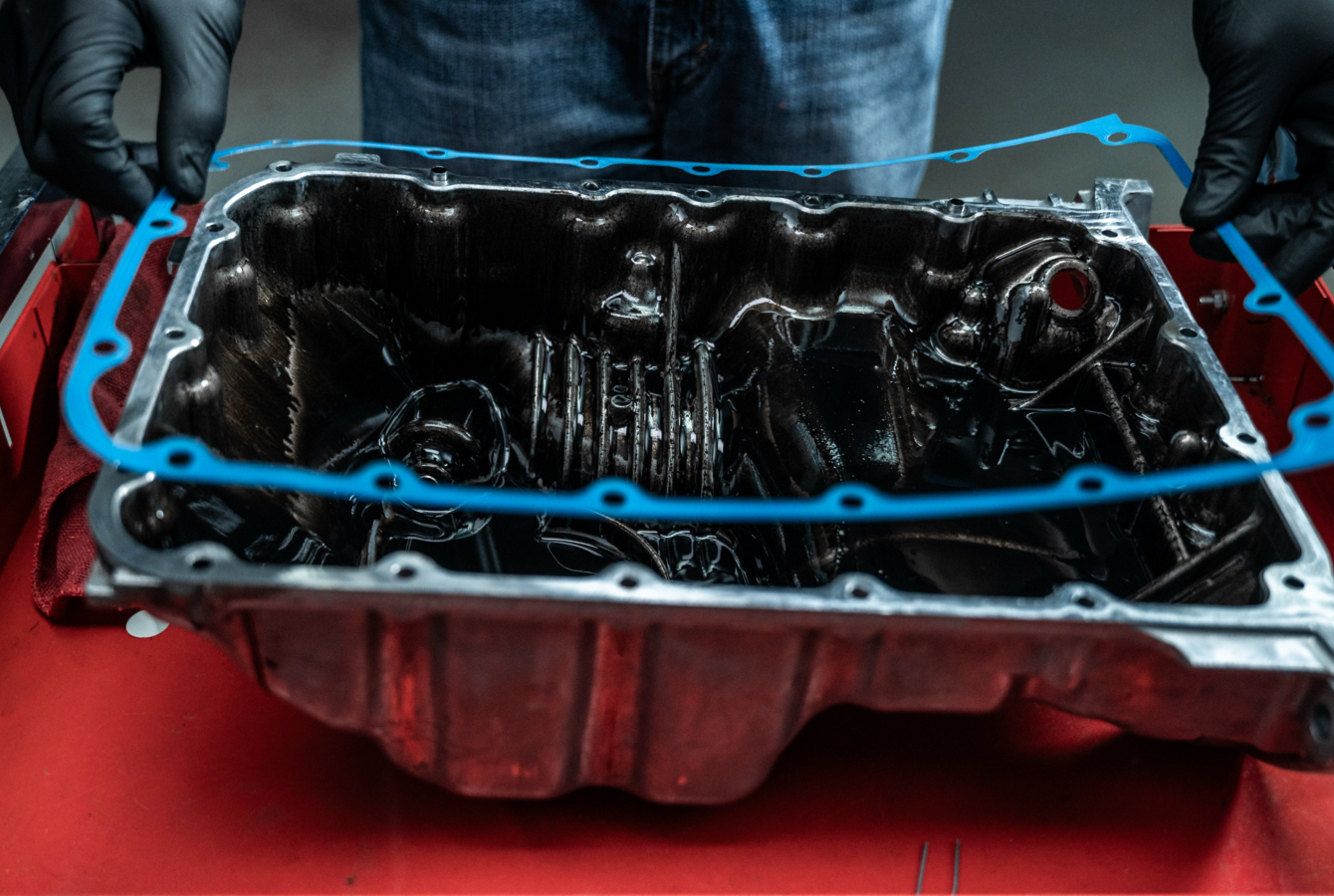

The engineers at Fel-Pro understand that the vehicles that technicians are working on have been on the road for many miles and have seen their share of wear and tear. As the years and mileage pile up, the engine and its components are no longer the same as when it rolled out of the factory.

For gaskets, sealing surfaces are no longer pristine after being exposed to high heat, fluids and casting motion. Over time, this exposure can lead to surfaces becoming worn, pitted and corroded and castings becoming out of flat. When repairing these vehicles, auto technicians need gaskets that can conform and compensate for minor surface imperfections.

Designing Gaskets for the Aftermarket

At Fel-Pro, “Designed for the Repair Environment” is more than a slogan, it is your assurance that Fel-Pro gaskets are made with the professional technician in mind. From engineering and research & development to manufacturing and testing, Fel-Pro engineers take pride in creating gaskets that meet the real-world challenges that technicians face every day.

To create gaskets that technicians can count on, Fel-Pro engineers don’t simply copy the original design. Improving up on the OE design, when appropriate, is a key part of Fel-Pro’s Designed for the Repair Environment philosophy. Fel-Pro master technicians and engineers start by examining each repair procedure. By thoroughly understanding the steps to completing the repair, Fel-Pro engineers can determine if there are pain points that could be alleviated with changing the design of the gasket.

Improving upon the OE design of a gasket can be done in different ways. It can mean changing the design, using different materials or employing one of Fel-Pro’s proprietary technologies. The Fel-Pro team analyzes the requirements of the repair when deciding upon the final design of a gasket. Fel-Pro uses the right design, right material and right technology to create a reliable seal for each gasket.

Application-Specific Designs

From sedans to trucks, modern vehicles have different designs and sealing needs which means a one-size-fits-all approach doesn’t work with these complex vehicles. Fel-Pro leads the industry in developing application-specific gaskets for the specialized sealing needs of each vehicle. By creating application-specific designs, Fel-Pro strives to solve the unique repair challenges technicians face in the real world.

Extensive Testing Ensures Quality

Designing the gasket is just the first step in the development process. To ensure that a gasket is ready for the repair environment, it undergoes exhaustive testing at the Fel-Pro Field Test Garage. Gaskets are installed on the vehicles of real people where they are driven in the real world and subjected to a wide range of conditions that can’t be replicated in the lab. This rigorous on-vehicle testing is vital to ensuring that the gasket is up to the standards of the technicians that install them.

Each year, the Field Test Garage logs nearly a million miles while testing new designs, technologies, coatings and materials. The information that the Fel-Pro team gets from testing is crucial to developing The Gaskets Professionals Trust™. Technicians can install Fel-Pro gaskets with confidence knowing they are real-world tested, real-world proven and up to the challenge of sealing the imperfect surfaces found in the repair bay.

Best-in-Class Manufacturing

Once a design is approved it takes a skilled manufacturing team to get the gasket built and into the hands of technicians. Using the best equipment and materials at its Skokie, Ill., facility, the talented Fel-Pro team builds quality into every step of the manufacturing process with a sharp focus on consistent performance. The entire team takes pride in making gaskets that technicians can install with confidence.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.

The content in this article is for informational purposes only. You should consult with a certified technician or mechanic if you have questions relating to any of the topics covered herein. Tenneco will not be liable for any loss or damage caused by your reliance on any content.

Other Parts For Your Vehicle

Fel-Pro® offers a wide variety of auto parts for all your vehicle needs.

Check them out today!