inside the problem

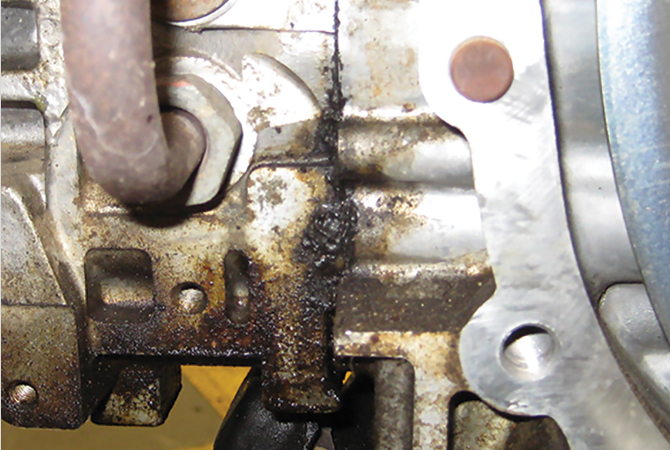

Fig 1. External oil leak from failed gasket

The EJ-series 2.5L boxer engine has been powering many of Subaru’s vehicles since its introduction in 1996. There are many different variations of this engine; some are SOHC and others are DOHC. Many are naturally aspirated, while others are turbocharged. Despite these differences, all of these engines share the potential for developing head gasket leaks.

The OE gaskets were composite or early-generation Multi-Layer Steel (MLS) gaskets, and both designs can be prone to leaks. Shortly after installation, these gaskets tend to leak combustion gasses or coolant internally, often resulting in an oily residue or smell in the coolant overflow bottle leading to coolant loss and overheating. As these gaskets age, they tend to develop external coolant and/or oil leaks which are initially noticed by the smell of oil or coolant burning off the exhaust system and are seen at the head gasket joint.

causes

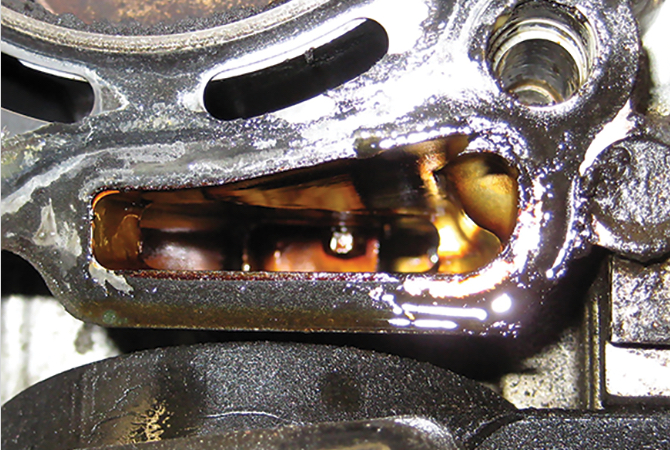

Fig 2. Head gasket damage resulting in external leak

For these Subaru head gaskets, there are many factors that cause leaking, but most experience a combination of these issues.

- Heat cycles: Even though the motors are all aluminum and the heads and block expand at the same rate, these lightweight castings flex as they heat and cool, scrubbing away at the OE composite gasket and the coating on the OE MLS gasket.

- Boxer engine configuration: Subaru uses boxer or flat horizontally opposed engines exclusively in their vehicles. In a flat engine, the cylinders are parallel to the ground instead of angled up in an inline or V configuration. This means that oil remains in contact with the head gaskets instead of draining back to the oil pan when the engine is shut off. Over time, oil can cause an inferior head gasket to deteriorate.

- Electrolysis: Many later-model Subarus experiencing external coolant leaks also have corrosion present on the battery and/or on the ground cable for the battery. While it sounds strange, the extra resistance causes electrolysis in the cooling system, causing the coolant to become corrosive.

- Abnormal combustion: Head gasket failure can occur on naturally aspirated 2.5L Subaru engines due to detonation or pre-ignition. It is more common for owners of turbocharged models to experience this type of failure though, due to increased cylinder pressures. This issue is further multiplied because many owners of turbocharged Subarus modify the engine and increase boost pressure to increase the power output. This creates even higher cylinder pressures and temperatures, which increase the likelihood of abnormal combustion.

The Solution: Fel-Pro PermaTorque® MLS Head Gasket

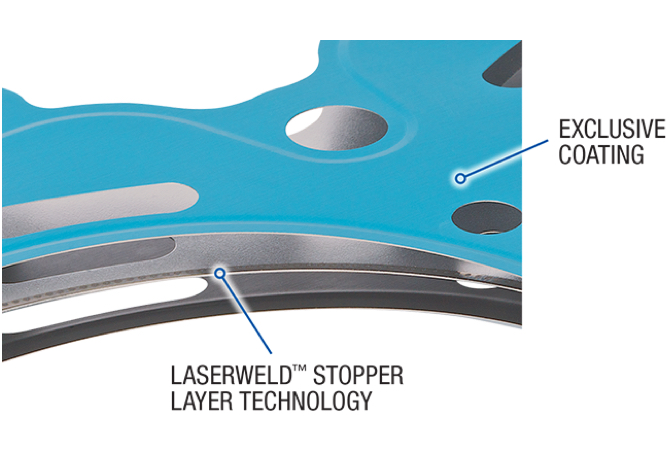

Fel-Pro®’s PermaTorque® MLS head gasket with LaserWeld™ stopper layer technology provides a reliable seal that addresses head gasket problems. PermaTorque MLS gaskets are designed on an application-specific basis, using multiple layers of full-hard stainless steel with embossed beads and specialized coatings.

The sealing beads function like springs and maintain sealing stress through heat cycling under extreme conditions. The exclusive coating negates the possibility for excessive scrubbing as the castings expand and contract. The coating also compensates for surface finishes as rough as 80 Ra, instead of the 30 Ra or less often required by OE MLS head gaskets.

On demanding applications like the Subaru 2.5L engine, Fel-Pro incorporates LaserWeld, a laser-welded stopper layer that improves sealing, originally developed for use in stock car racing and proven to hold up to the most extreme conditions. The LaserWeld stopper layer precisely controls and limits the compression of the multiple layers within an MLS head gasket to ensure proper sealing stress.

This stopper layer withstands cylinder pressure which helps to promote extended head gasket life and allows the gasket to perform exceptionally well in engines with performance enhancements. Learn more about Fel-Pro PermaTorque MLS head gaskets.

Installation Tips

As with most engines that use torque-to-yield head bolts, it is important to install new head bolts when servicing Subaru 2.5L head gaskets to ensure proper bolt loading, even though the OE may not recommend new head bolts. Installing new head bolts is good insurance for a long-lasting sealing job. The old head bolts have seen countless heat cycles and combustion events. Learn more about the correct torquing sequence and specifications when installing.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.