Preventing Overheating

Whether you’re rebuilding or repairing an engine, preventing overheating is paramount to the longevity and durability of the vehicle. Controlling the engine temperature prevents damage from overheating that can include gasket failure, casting warpage and severe engine damage.

While the thermostat, radiator and coolant all play a big role in regulating engine temperature, they aren’t alone. Head gaskets, with their precisely shaped-and-sized holes to meter the flow of coolant through the engine, also help prevent overheating.

Inside the Design of Fel-Pro® Head Gaskets

When replacing the head gasket with a Fel-Pro head gasket, you may notice that the coolant holes have a different size or position compared to the engine block and cylinder head. Is this normal? Does this affect the cooling capabilities of the Fel-Pro head gasket? To answer these questions, let’s explore the relationship between overheating and the size and/or position of coolant holes in Fel-Pro head gaskets.

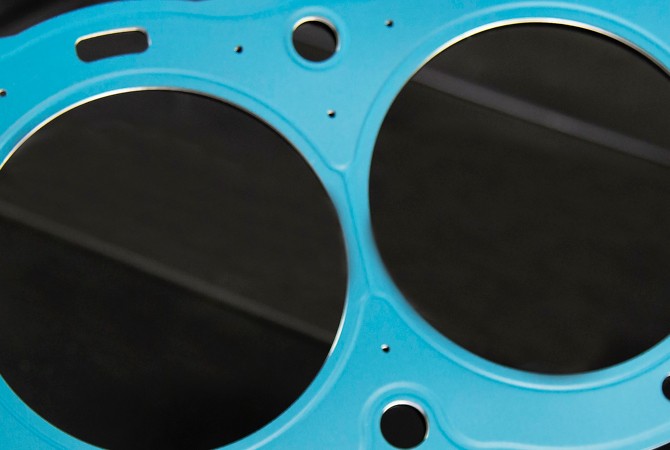

On the left is the bare casting and on the right is the casting with a Fel-Pro head gasket installed on a Big Block Chevy Engine. The coolant holes in the block casting are much larger than those in the Fel-Pro head gasket; this is by design.

Controlling Coolant Holes

Besides the reduction in size of the top coolant holes, the large coolant hole on the bottom right of the superimposed gasket above is partially blocked off. There are also holes in the gasket which are not open in the block. Some Big Block Chevy engines have these holes while others do not. This will depend on the generation, application and the intended use of the block. These are not design flaws or oversights – the size and placement of every hole in the gasket is intentional, and this is true for every Fel-Pro gasket.

Why Fel-Pro Uses Smaller Holes or Blocks Off Some Holes

The holes in head gaskets meter the flow of coolant properly through the heads. In most engines, coolant flows from the water pump at the front of the engine block toward the rear, goes up into the head(s), to the thermostat and finally to the radiator once the thermostat opens before returning back to the water pump.

An improperly sized or placed hole can create a shortcut which prevents coolant from following the correct path through the engine. If the coolant takes a shortcut because a coolant hole is too large at the front of the engine, the rear cylinders can overheat. If the holes are properly placed, but too large, the coolant can pass through the engine too quickly and fail to absorb enough heat, also resulting in overheating.

So why are the castings made with holes that are larger than they should be or unneeded for proper coolant flow? Engine blocks and heads are sand-cast, meaning sand forms the mold for the casting. The holes must be large enough, and sometimes extra holes must be added, to allow the sand to be completely cleaned from the casting once it has solidified. On older engines, the holes may not always line up due to core shift – that is, the blocks are not always perfectly cast, so the gasket needs to accommodate the fact that different castings may have slightly different hole positioning.

Bottom Line

Generally, the coolant metering holes in the Fel-Pro gasket will match the metering holes in the OEM gasket, determined by the engine manufacturer at the time the engine was designed and developed. While the visual differences between the block, cylinder head and gasket holes may seem extreme, you can install Fel-Pro gaskets with confidence because every hole is precisely placed and sized to ensure that coolant flow is properly controlled by the head gasket.

With this in mind, a Fel-Pro head gasket should never be modified in any way – doing so not only prevents proper coolant flow, but also can affect the gaskets ability to seal, as the specialized coatings can be damaged.

Learn more about Fel-Pro quality gaskets that are specifically designed for the repair environment, find your car part, or find where to buy your auto part today.

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

Other Parts For Your Vehicle

Fel-Pro® offers a wide variety of auto parts for all your vehicle needs.

Check them out today!